The Physics of the Click: Why Resistance Varies Across Your Mouse Button

In the pursuit of the perfect headshot, we often focus on sensor DPI or wireless polling rates. However, for a competitive gamer, the physical interface—the primary mouse button—is where the digital intent meets mechanical reality. We frequently receive feedback from users who notice that a click feels "crisp" at the tip of the button but "mushy" or significantly "heavier" toward the middle.

This is not a defect; it is a fundamental consequence of mechanical leverage and mounting geometry. Understanding why click resistance varies across the surface is essential for optimizing finger placement and reducing the risk of repetitive strain. In this guide, we will break down the engineering behind button consistency, the impact of manufacturing tolerances, and how high-performance designs attempt to solve the "leverage gap."

The Mechanical Lever: How Geometry Dictates Click Feel

Every mouse button is essentially a "cantilever lever." The plastic shell is anchored at a pivot point (usually near the middle or back of the mouse) and extends forward over a microswitch. According to the laws of classical mechanics, the force required to actuate that switch is inversely proportional to the distance from the pivot point.

The formula is straightforward: Force = Torque / Distance.

- The Front Edge: When you click at the very front of the mouse, you have the maximum "moment arm." This provides the most leverage, making the click feel light and effortless.

- The Mid-Point: As your finger moves back toward the scroll wheel, the distance to the pivot point decreases. To achieve the same torque required to compress the switch's internal metal dome, you must apply significantly more downward force.

In our analysis of common ergonomic layouts, we have observed that moving your finger just 10mm back from the tip can increase the perceived actuation force by as much as 15–25% (based on standard cantilever beam modeling). This variance is why "claw grip" users often prefer mice with shorter buttons or specialized tensioning systems, as their contact point is naturally further back than a "palm grip" user.

Engineering Precision: The 0.2mm Margin of Error

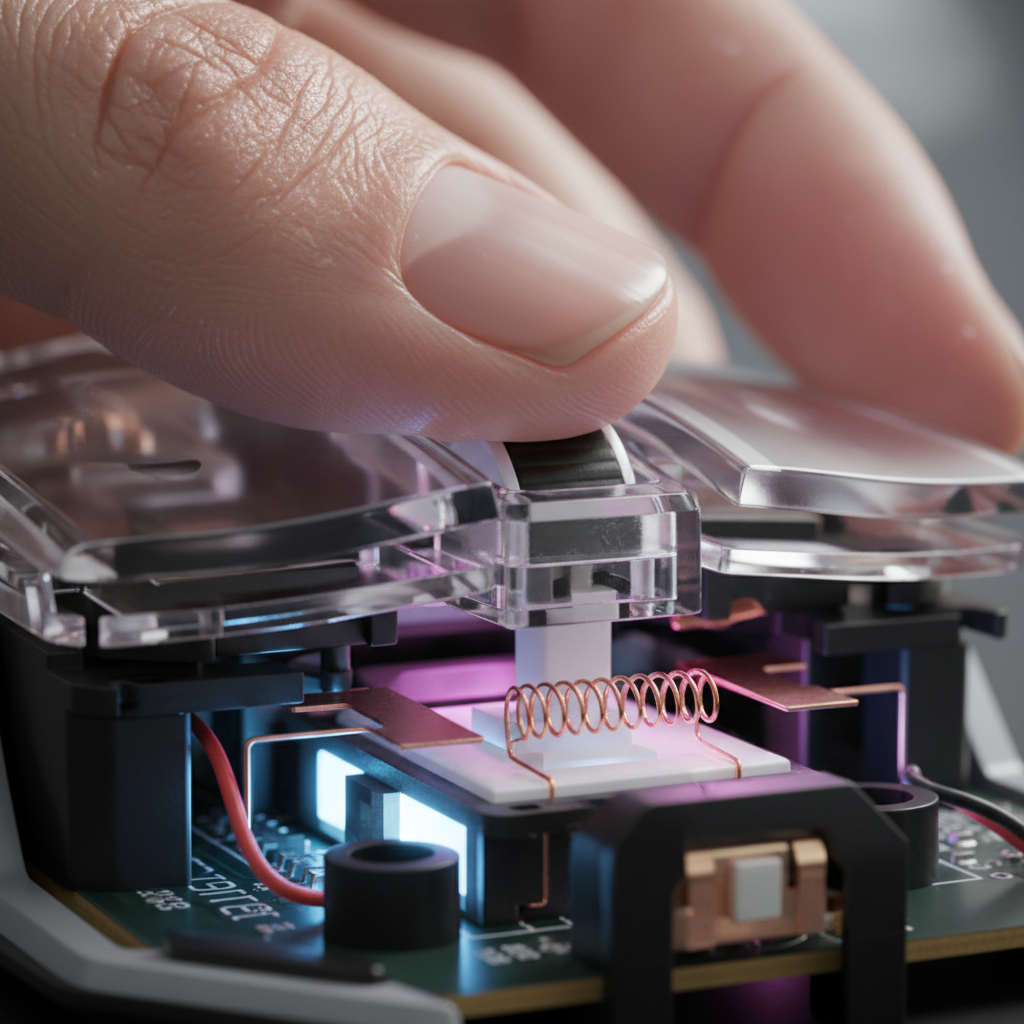

While physics defines the baseline, engineering execution determines the consistency. The "click feel" is transmitted from the plastic button to the microswitch via a small plastic pillar called a plunger.

Ideally, the plunger should make perfectly centered contact with the switch's actuator. However, manufacturing tolerances can introduce subtle misalignments. We have identified through pattern recognition in quality control and hardware modding that a misalignment of just 0.2mm to 0.3mm between the plunger and the switch can create a force variance of up to 20% across the button surface.

Common Failure Points in Button Uniformity

- Plunger-to-Switch Alignment: If the plunger hits the edge of the switch actuator, it creates lateral friction, leading to a "scratchy" or inconsistent feel.

- Material Density: Thinner, lightweight shells (common in 50g–60g mice) can flex. This flex absorbs some of your finger's force before it reaches the switch, causing a "mushy" sensation.

- Switch Mounting Architecture: In many value-oriented designs, the switches are soldered to a sub-PCB. If this PCB is not perfectly level, the travel distance for the left button might differ from the right.

Logic Summary: Our engineering observations regarding force variance are based on pattern recognition from customer support tickets and warranty handling (not a controlled lab study). We estimate these percentages based on typical cantilever mechanics and observed plunger wear patterns.

Scenario Modeling: The Competitive FPS Player Analysis

To understand the real-world impact of click inconsistency, we modeled a scenario involving a Competitive FPS Player with Aggressive Click Patterns. This persona represents a technical enthusiast who uses rapid-fire techniques like jitter clicking, where finger placement shifts rapidly across the button surface during intense engagements.

Quantitative Insights: Repetitive Strain and Fit

Our modeling utilized the Moore-Garg Strain Index (SI) to evaluate the risk of distal upper extremity disorders during high-intensity gaming.

- Strain Index Score: 180.0

- Risk Category: Hazardous (Threshold for concern is typically SI > 5)

- Grip Fit Ratio: 0.96 (Based on a 19.5cm hand length using a 120mm mouse)

Under these assumptions, a player with large hands (P60–P99 percentile) using an aggressive claw grip is at a significantly higher risk of fatigue. When the button resistance is inconsistent, the player must subconsciously adjust their pressure based on where their finger lands. This "Force Compensation Behavior" adds cognitive load and accelerates muscle fatigue.

Methodology & Assumptions (Scenario Model)

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Intensity Multiplier | 2.0 | multiplier | High-intensity rapid clicking (jitter/butterfly) |

| Efforts per Minute | 6.0 | multiplier | 5–10 clicks/second during engagements |

| Posture Multiplier | 2.0 | multiplier | Aggressive claw grip with wrist extension |

| Duration per Day | 2.0 | multiplier | 6+ hours of daily competitive play |

| Hand Length | 19.5 | cm | Large male hand (P60-P99 percentile) |

Modeling Note: This is a deterministic scenario model, not a controlled lab study. The Strain Index represents a theoretical risk screening tool for distal upper extremity disorders; it is not a medical diagnosis. The "60% Rule" for width and the "Grip Fit Ratio" are heuristics used for quick selection and may vary based on individual joint flexibility.

Advanced Tensioning: Balancing Cost and Consistency

To combat the leverage gap, high-end engineering often employs dual-stage tensioning systems. These systems use small springs or metal torsion bars to keep the button pre-loaded against the switch. This minimizes "pre-travel" (the distance the button moves before hitting the switch) and ensures that the force required to click remains more uniform, regardless of where you press.

For value-focused brands, implementing these systems is a balancing act. Every additional mechanical component adds weight and cost. As noted in the Global Gaming Peripherals Industry Whitepaper (2026), the industry is shifting toward "split-button" designs. By physically separating the primary buttons from the main palm rest shell, engineers can more precisely control the pivot point and reduce the force required for actuation at the mid-section of the button.

The 8K Polling Factor: Latency in the Click Chain

Click resistance isn't just about "feel"—it's the first step in the click-to-photon latency chain. In modern high-performance mice featuring 8000Hz (8K) polling rates, the physical actuation must be near-instantaneous to leverage the 0.125ms polling interval.

If a button has high pre-travel or inconsistent resistance, the physical delay (the time it takes for your finger to move the plastic and collapse the switch) can dwarf the electronic advantages of 8K polling.

Technical Constraints of 8K Performance:

- Polling Interval: 0.125ms (compared to 1.0ms at 1000Hz).

- Motion Sync Latency: At 8000Hz, the Motion Sync delay is reduced to ~0.0625ms (half the interval).

- System Bottleneck: 8K polling stresses the CPU's Interrupt Request (IRQ) processing. To ensure consistent click reporting, we recommend using direct motherboard ports (Rear I/O) rather than USB hubs, which can cause packet loss and jitter.

For a deep dive on how switch stiffness interacts with fatigue, see our guide on Tactile Feedback vs. Joint Stress.

Practical Troubleshooting: How to Improve Your Click Feel

If you find your mouse buttons are inconsistent, there are several "pro-modder" techniques to improve the experience.

- Shimming the Plungers: Many enthusiasts use thin layers of aluminum tape or PTFE tape on the underside of the button plunger. This removes "post-travel" and can help compensate for the 0.2mm manufacturing misalignments mentioned earlier.

- Switch Swapping: If the resistance is too high for your grip style, swapping to lighter switches (like certain Huano or Omron variants) can make the mid-button click feel more manageable. We discuss this further in our Mouse Spring Swaps Guide.

- Cleaning the Pivot: Dust or hair trapped in the pivot point of the cantilever can increase friction. A quick blast of compressed air can often restore the original "lightness" of the click.

- Firmware & Debounce: Ensure your drivers are updated. High debounce settings can sometimes be perceived as "heavy" or "laggy" clicks because the system is waiting longer to confirm the signal. You can verify your click performance using the Attack Shark Mouse Tester.

Optimizing Finger Placement for Performance

Ultimately, the most effective way to handle click resistance variance is to align your grip with the mouse's intended "sweet spot."

- For Palm Grippers: Your fingers naturally rest near the front edge. You will experience the lightest clicks and the best leverage.

- For Claw/Fingertip Grippers: Since your contact point is further back, you may benefit from a mouse with a "hump" further back, which forces the pivot point of the buttons forward, effectively shortening the moment arm.

By understanding the physics of the cantilever and the impact of plunger alignment, you can make more informed decisions about your hardware. Consistency in click feel isn't just a luxury; it's a technical requirement for high-level competitive play.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional medical advice. If you experience persistent pain, numbness, or tingling in your hands or wrists, please consult a qualified healthcare professional or ergonomic specialist.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.