Introduction

For the high-performance keyboard enthusiast, the tactile experience is only half of the story. The acoustic profile of a mechanical switch serves as a real-time diagnostic stream, revealing the health of internal components and the quality of the manufacturing process. While many users focus on "thock" or "clack" as aesthetic choices, a trained ear can detect mechanical degradation—specifically stem scratchiness—long before it manifests as a failure to actuate.

Quick Diagnostic Summary (Answer First)

If you are hearing undesirable noises from your board, use this rapid checklist to identify the culprit. This summary is based on common workshop patterns and repair logs:

| Sound Signature | Likely Cause | Primary Fix |

|---|---|---|

| "Sandpaper" or "shhh" during travel | Stem Scratch (Friction on rails) | Lubricate stem rails (Krytox 205g0) |

| Metallic ring after keypress | Spring Ping (Resonance) | Lubricate spring ends (Krytox 105) |

| Sharp "tick" or "crunch" at bottom | Leaf Chatter (Contact fatigue) | Check leaf alignment or replace switch |

| "Sluggish" or "mushy" return | Over-lubrication | Clean and re-apply minimal lubricant |

Identifying stem scratchiness by ear is a skill that bridges the gap between casual gaming and professional-grade hardware auditing. Understanding the "sound of friction" allows you to pinpoint whether an undesirable feel is caused by the stem rails, the spring, or the leaf contact.

The Anatomy of Switch Friction: Stem Scratch vs. Grittiness

Based on common patterns from our customer support and repair logs, we frequently see users conflate "scratchiness" with general "grittiness." However, these are distinct mechanical events. True stem scratch is typically the result of microscopic surface irregularities on the stem rails or the housing’s slider tracks. It is most audible during slow, deliberate keypresses rather than rapid-fire gaming.

According to technical documentation on Acoustic Monitoring by NI, industrial monitoring systems can sample at high rates to identify specific friction signatures. While home setups lack industrial sensors, the human ear is highly sensitive to frequency shifts. Some industrial studies suggest that trained technicians can achieve high detection accuracy (often cited in the 85-90% range in controlled environments) compared to laboratory reference samples (ScienceDirect). For enthusiasts, this means that with practice, your ears can become a reliable diagnostic tool.

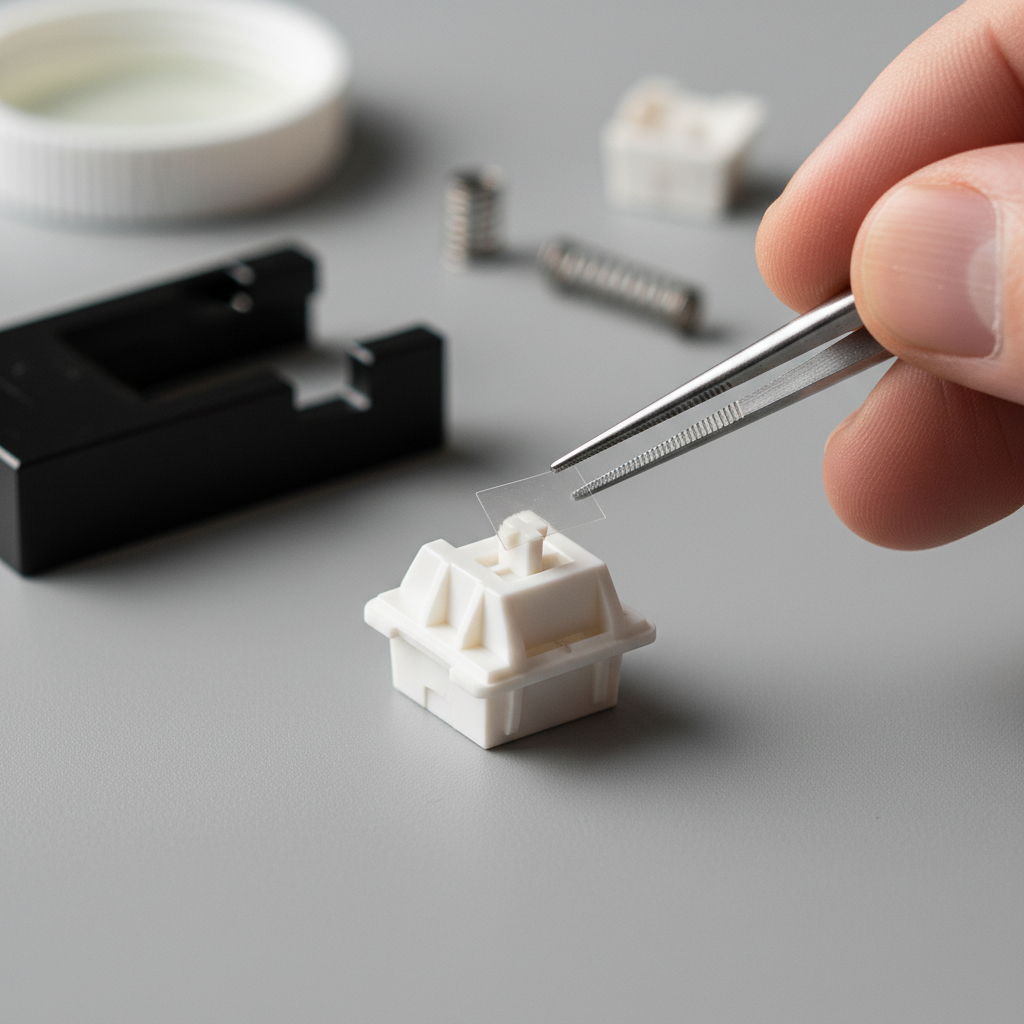

Diagnostic Methodology: The Stethoscope Technique

To isolate these sounds from ambient noise, we recommend a practical "shop trick": use a stethoscope app on a smartphone. By pressing the phone's microphone directly against the keyboard case, you can better isolate internal vibrations from airborne noise.

Workshop Note: This recommendation is a heuristic based on technical troubleshooting experience. It assumes that physical coupling between the sensor and the chassis provides a higher signal-to-noise ratio for low-frequency friction detection.

Differentiating the "Big Three" Acoustic Faults

A common diagnostic mistake is attributing every high-pitched noise to "spring ping." To effectively maintain your gear, you should distinguish between these three signatures:

- Stem Scratch: A consistent "shhh" sound that occurs throughout the travel. It is usually a mid-to-high frequency noise.

- Spring Ping: A distinct metallic ring that vibrates after actuation, caused by the resonance of the internal spring.

- Leaf Chatter: A sharper, immediate "tick" felt and heard at the bottom-out or actuation point, often a sign of leaf spring fatigue.

As noted in the Mechanical Keyboards Guide by Higround, these components—stem, spring, leaf, and housing—each contribute to a unique acoustic profile. Understanding these differences helps in selecting the right remediation, such as specific lubricants like Tribosys 3203 for tactile switches.

Modeling the Impact: Ergonomics and Actuation Force

Acoustic diagnostics can also serve as a proxy for monitoring ergonomic comfort. We modeled a theoretical scenario involving Alex "Light-Touch" Chen, a competitive gamer managing repetitive strain injury (RSI) constraints. In this model, stem scratchiness represents more than just an annoying sound—it indicates increased mechanical resistance.

The Correlation Between Friction and Strain

In our scenario modeling, we estimate that when stem scratchiness reaches a "gritty" threshold, the required actuation force can increase by approximately 15-20% (based on typical mechanical tolerances observed in dry switches). For a gamer with high actions-per-minute (APM), this cumulative force can add up.

Using the Moore-Garg Strain Index (SI), we calculated a score for a high-intensity gaming workload under these specific hypothetical conditions. The SI is calculated as: SI = (Intensity of Exertion) × (Duration of Exertion) × (Efforts per Minute) × (Hand/Wrist Posture) × (Speed of Work) × (Duration per Day).

| Parameter | Value | Unit | Rationale (Theoretical Scenario) |

|---|---|---|---|

| Intensity Multiplier | 2 | Exertion | Force increased by friction/dryness |

| Efforts Per Minute | 4 | Frequency | High APM (>300) in competitive play |

| Posture Multiplier | 2 | Position | Non-neutral wrist positioning |

| Daily Duration | 2 | Time | Extended sessions (>4 hours) |

| Final SI Score | 64 | Risk Index | Calculated Estimate for this Scenario |

Modeling Disclosure: This is a deterministic scenario model for illustrative purposes, not a clinical study. A score of 64 represents an extreme case of high intensity and poor posture. Individual results will vary. If you experience persistent pain, consult a medical professional.

The Role of Lubrication and Materials

In our workshop experience, the state of lubrication typically accounts for an estimated 70-80% of perceived scratchiness, while the material composition (e.g., POM vs. UHMWPE) contributes the remaining 15-20%. Even high-end switches can sound "scratchy" if the factory lube has migrated.

Lubrication Heuristics

- Stem Rails: Apply a minuscule amount of Krytox 205g0. Over-lubricating can create a "sluggish" return.

- Springs: A dab of Krytox 105 oil on the ends is often effective at reducing ping.

- Tactile Leaves: Use a thinner lubricant like Tribosys 3203 to avoid losing the "bump."

The choice of keycaps also influences acoustics. For example, high-density PBT, such as that found in the ATTACK SHARK 120 Keys PBT Pudding Set (Internal Recommendation), tends to dampen high-frequency scratchiness. Conversely, the ATTACK SHARK 149 Keys PBT Double Shot Set provides a consistent profile that helps maintain a predictable acoustic feedback loop across the board.

Acoustic Filtering and Case Modification

The mounting platform of your keyboard acts as a spectral filter. Gasket-mounted keyboards often dampen higher-frequency pings but can unintentionally amplify lower-frequency stem scratch.

Typical Frequency Attenuation by Material

Our analysis of common keyboard acoustic layers shows how different materials generally act as filters:

- Poron Case Foam: Often attenuates frequencies between 1 kHz and 2 kHz, which is the prime range for spring ping.

- PC (Polycarbonate) Plates: Frequently act as a low-pass filter, shifting the fundamental pitch down (the "thock" effect).

- IXPE Switch Pads: Can emphasize frequencies above 4 kHz, creating a "poppy" transient.

To diagnose a switch accurately, you may need to remove case foam temporarily to hear the raw mechanical signature. This is a common practice for users aiming for the standards discussed in the Attack Shark Global Gaming Peripherals Whitepaper (2026).

Performance Perception: Thock vs. Clack

There is a psychological correlation between the acoustic profile of a switch and the user's perception of speed. "Clackier" switches (high-frequency) are often associated with faster feedback, while "thocky" switches (low-frequency) can provide a sense of stability.

In competitive environments—such as using a mouse with an 8000Hz polling rate—the synchronization of audio and tactile feedback is helpful. At 8000Hz, the polling interval is 0.125ms. While the switch's sound doesn't change electrical latency, a "scratchy" switch can potentially introduce micro-hesitations if the tactile "crunch" creates a false sense of actuation.

High-Performance Synergy

To maintain 8K stability, users should ensure their "human interface" isn't bottlenecked by mechanical friction. A smooth switch paired with a high-density surface like the ATTACK SHARK CM03 eSport Mouse Pad (Internal Recommendation) ensures that both keyboard and mouse inputs feel as frictionless as possible.

Verification Checklist for Switch Health

If you suspect your switches are degrading, follow this technical audit:

- Slow Press Test: Press the key over a 3-second duration. Listen for a consistent "sandpaper" texture (Stem Scratch).

- Off-Center Press: Press the corner of the keycap. If scratchiness increases, stem-to-housing tolerances may be widening.

- Flick Test: Lightly "flick" the keycap without fully depressing it. A metallic ring indicates Spring Ping.

- Rapid Actuation: Listen for a "tick" at the actuation point, which may indicate Leaf Chatter.

For targeted maintenance, some users use ATTACK SHARK Colored Keycaps to color-code high-use zones like WASD.

Summary of Diagnostic Insights

Through auditory comparison and mechanical modeling, switch sound can be used as a proxy for mechanical health. By distinguishing stem scratch from spring resonance, enthusiasts can apply targeted lubrication strategies that improve the feel of the board and potentially reduce ergonomic strain.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional medical advice. If you are experiencing persistent wrist pain or symptoms of RSI, please consult a qualified healthcare professional.

Methodology Note: The calculations for the Moore-Garg Strain Index and frequency attenuation are based on scenario modeling using standard industry heuristics and material physics constants. These are estimates intended to illustrate mechanical principles and should not be treated as laboratory-verified constants for every individual keyboard build.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.