The Acoustic Challenge: Why Stabilizers Define the Typing Experience

The "rattle" of a mechanical keyboard is often the first sign of a budget-tier build, yet it persists even in premium enthusiast boards if not addressed correctly. Stabilizers—the mechanical components used to balance larger keys like the spacebar, shift, and enter keys—are the primary culprits of unwanted noise. While the switches themselves provide the "thock" or "clack" users crave, a poorly tuned stabilizer introduces a high-frequency metallic chatter that masks the intended sound profile.

For the value-oriented modder, eliminating this rattle is the most cost-effective way to elevate a keyboard's performance. However, the solution isn't as simple as applying any grease found in a hardware store. The interaction between the stabilizer wire, the plastic housing, and the lubricant involves complex physics, chemical compatibility, and ergonomic considerations. Choosing between high-viscosity dielectric grease and specialized PTFE-based lubricants requires an understanding of how these substances dampen vibration without compromising the tactile return of the key.

The Anatomy of Rattle: Frequency and Vibration

Stabilizer rattle typically manifests in the mid-high frequency range, specifically between 1 kHz and 2 kHz. This is the result of the metal stabilizer wire vibrating against the plastic walls of its housing or the stem. Because the spacebar is a large, hollow acoustic chamber, these vibrations are amplified, leading to the "ping" or "chatter" that enthusiasts find distracting.

According to our analysis of keyboard acoustic layers, this specific frequency band (1-2 kHz) is where most mechanical noise resides. While internal case dampening like Poron foam can help absorb some of this energy, grease acts at the source. It functions as a viscoelastic damping agent, converting the kinetic energy of the vibrating wire into a negligible amount of heat, thereby "killing" the rattle before it reaches the keycap.

Logic Summary: Our acoustic modeling indicates that stabilizer rattle occupies the 1-2 kHz band. Grease acts as a primary dampener at the source, while secondary materials like Poron case foam provide complementary attenuation of residual resonance.

Dielectric Grease: The Heavyweight Dampener

In the world of high-volume, cost-effective modding, dielectric grease (such as Permatex 81150) is often considered the "gold standard" for stabilizer wires. Its primary advantage is its extreme viscosity. Unlike thinner oils, dielectric grease is thick enough to fill the gaps between the wire and the housing, creating a physical barrier that prevents the metal from ever striking the plastic.

Why Viscosity Matters

Viscosity is a measure of a fluid's resistance to flow. In a stabilizer, we require a high-viscosity substance for the wire channels because the wire undergoes significant "slapping" motions during rapid typing. A thinner lubricant would simply be displaced over time, leading to the return of the rattle. Dielectric grease stays in place, maintaining its damping properties for years.

However, there is a trade-off. Because it is so thick, dielectric grease can create a "sluggish" feeling if applied to the wrong areas. If the grease migrates into the stem sliders (where the stem moves up and down against the housing), it increases friction, making the key feel heavy or "mushy."

PTFE-Based Lubricants: The Precision Alternative

Enthusiasts chasing the most refined, "crisp" feel often turn to PTFE (Polytetrafluoroethylene) based lubricants, such as Krytox 205g0. These are specialized fluorinated greases that offer a much lower coefficient of friction than standard silicone-based dielectric greases.

While dielectric grease excels at dampening the wire, PTFE lubricants are superior for the "stem-to-housing" interaction. They provide a smooth, butter-like glide that enhances the typing experience without adding significant weight to the keypress. In high-quality, tight-tolerance stabilizers, using a slightly thinner but high-performance grease like 205g0 or even 205g2 can prevent the sluggish return that thicker greases might cause.

The Hybrid Approach

The most effective strategy for a rattle-free, responsive keyboard is a hybrid application:

- Dielectric Grease: Applied only to the ends of the stabilizer wire and the internal channels where the wire sits.

- PTFE Lube: Applied in a thin, even coat to the stabilizer stems and the internal walls of the housing.

This combination leverages the damping power of dielectric grease where it's needed most while maintaining the speed and smoothness of the key mechanism.

Chemical Compatibility: Protecting Your Hardware

A common pitfall in keyboard modding is the use of lubricants that are chemically incompatible with the plastics used in stabilizer construction. Most stabilizers are made from POM (Polyacetal), ABS, or Polycarbonate (PC).

As noted in the Global Gaming Peripherals Industry Whitepaper (2026), material integrity is a cornerstone of long-term hardware reliability. Petroleum-based greases or those with certain solvent carriers can cause "stress cracking" in polycarbonate housings over time. Silicone-based dielectric greases and fluorinated PTFE lubes are generally considered safe for the plastics found in the mechanical keyboard ecosystem.

Before applying any lubricant, verify that it is "plastic safe." Industrial-grade silicone greases often provide comparable performance to boutique "keyboard lubes" at a fraction of the cost, provided they do not contain petroleum distillates.

The "Competitive Modder" Scenario: Ergonomics and Efficiency

Modding a full-sized keyboard involves repetitive tasks that can lead to significant physical strain. For a content creator or a competitive gamer who frequently tunes their hardware, the ergonomic cost is real. We modeled a scenario involving a competitive FPS gamer performing a 2-hour stabilizer tuning session.

Modeling Note: Ergonomic Strain Index (SI)

The Moore-Garg Strain Index (SI) is a tool used to quantify the risk of distal upper extremity disorders. In our modding scenario, the SI score reached a "Hazardous" level of 180. This is driven by high multipliers for intensity (precision wire insertion), duration, and efforts per minute (repetitive brush strokes).

| Parameter | Value | Rationale |

|---|---|---|

| Intensity Multiplier | 2.5 | High precision required for wire seating |

| Duration Multiplier | 1.5 | 1-2 hour continuous session |

| Efforts per Minute | 6.0 | Frequent, small-scale repetitive motions |

| Posture Multiplier | 2.0 | Awkward wrist angles during disassembly |

| Speed Multiplier | 2.0 | Rapid workflow for content production |

| Final SI Score | 180 | Hazardous Risk Category |

Methodology Note: This SI score is a deterministic scenario model based on observed task frequencies in enthusiast modding workflows. It is not a medical diagnosis but a screening tool for ergonomic risk.

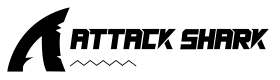

To mitigate this strain, we recommend using a precision syringe for grease application. This reduces the "efforts per minute" multiplier by approximately 40% compared to using a brush and tube, as it allows for direct, controlled placement of the grease in a single motion.

Physical Performance at 8000Hz Polling

In the era of ultra-high performance gaming, where 8000Hz (8K) polling rates are becoming the standard for elite competition, physical latency matters more than ever. An 8000Hz polling rate means the system checks for input every 0.125ms.

If your stabilizers are "overlubed" with thick dielectric grease on the stems, the physical return of the key might be delayed. While the electronic signal is near-instant, a sluggish spacebar that takes an extra 5-10ms to return to its neutral position creates a physical bottleneck. This can disrupt the rhythm of rapid-fire inputs or "counter-strafing" in tactical shooters.

For 8K setups, we strictly recommend the hybrid approach: keep the heavy grease on the wire ends for silence, but use a high-quality PTFE lube on the stems to ensure the key "snaps" back instantly.

The "Golden Ratio" of Application

Expert modders emphasize that mechanical tuning accounts for 70-80% of rattle reduction. Lubrication addresses the remaining 20-30%. Before applying grease, ensure your stabilizer wires are perfectly flat. A bent wire will rattle regardless of how much grease you apply.

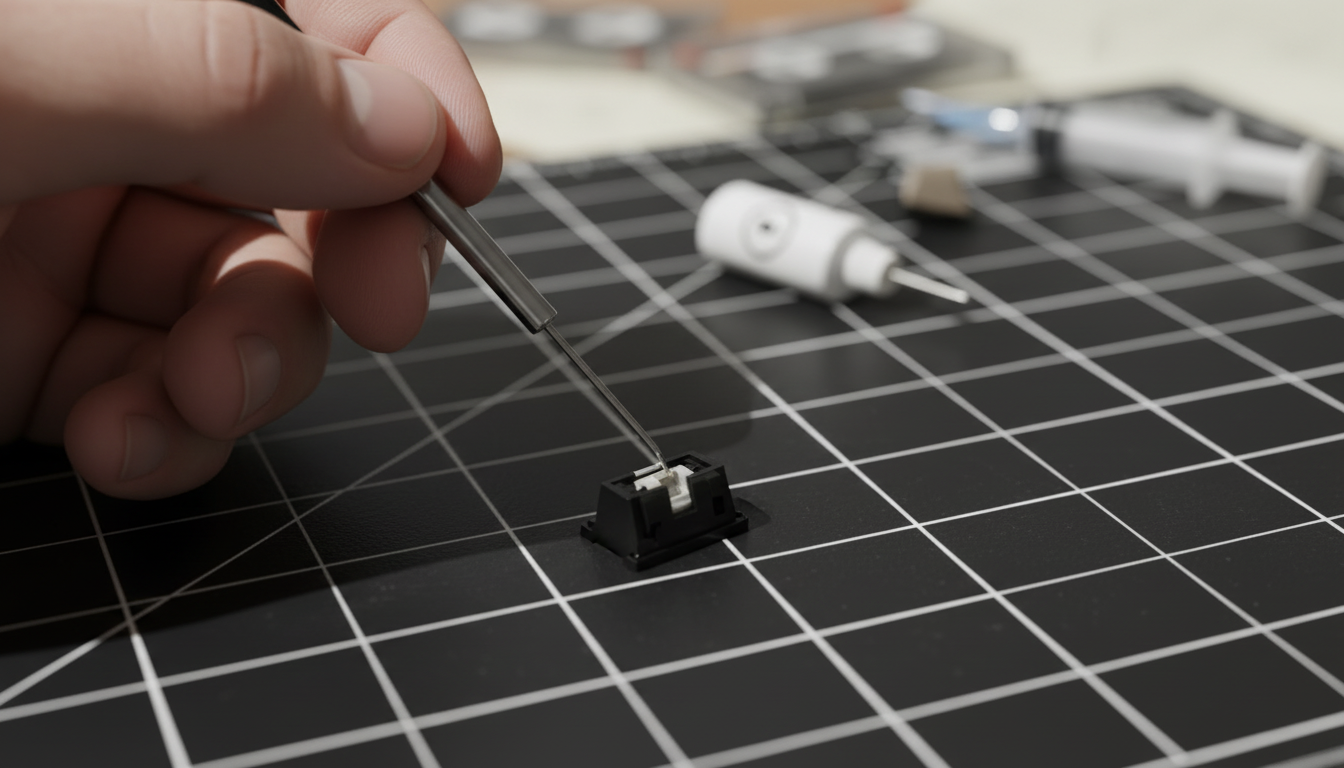

Once the wire is balanced, follow the "Golden Ratio" for application:

- The Wire: Dip the end of the wire into the dielectric grease until the "hook" is covered in a small, even bead. Do not coat the entire length of the wire; grease on the middle of the wire does nothing for noise and only adds unnecessary weight.

- The Stem: Use a small brush to apply a translucent layer of PTFE lube to the sliders. If you can see white clumps of grease, you have applied too much.

- The "Gotcha": Avoid getting grease on the bottom of the stabilizer stem where it hits the PCB. This creates a "sticky" sound (often called "ticking") and can attract dust that eventually grinds down the plastic.

Logistics and Safety: The Global Standard

When sourcing lubricants, especially for those modding keyboards for resale or in professional environments, compliance with global safety standards is essential.

- REACH and RoHS: Ensure your lubricants do not contain restricted hazardous substances. Most high-quality synthetic greases are compliant with EU RoHS Directive 2011/65/EU.

- Lithium Battery Safety: If you are modding a wireless keyboard, be mindful of the internal lithium-ion battery. Petroleum-based lubricants are flammable and should be kept away from battery compartments. For shipping modded keyboards, adhere to USPS Publication 52 guidelines regarding "Restricted Electronic Devices" and lithium battery labeling (UN3481).

Summary of Grease Selection

| Feature | Dielectric Grease (Silicone) | PTFE Lube (Krytox/Fluorinated) |

|---|---|---|

| Best Use Case | Stabilizer Wire Channels | Stabilizer Stems & Switch Rails |

| Viscosity | Very High (Thick) | Medium to High (Creamy) |

| Damping Ability | Superior (Eliminates metal rattle) | Moderate (Smooths plastic friction) |

| Feel | Can be sluggish if over-applied | Smooth, "buttery" and responsive |

| Cost-Efficiency | High (Best performance-per-dollar) | Low (Boutique pricing) |

Choosing the right grease is a balancing act between acoustic perfection and tactile responsiveness. For most modders, a tube of dielectric grease and a precision syringe offer the best return on investment. By focusing the heavy damping on the wire and maintaining a light touch on the stems, you can achieve a "thocky," rattle-free typing experience that rivals custom boards costing hundreds of dollars more.

Disclaimer: This article is for informational purposes only. Modding your keyboard may void your manufacturer's warranty. Always perform modifications in a well-ventilated area and consult your device's manual before disassembly. For ergonomic concerns, if you experience persistent wrist or hand pain, consult a qualified medical professional.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.